Several years ago we recognized that proof test coverage was an important variable that must be considered when doing PFDavg calculations. We ran some models and discovered that the difference between “perfect” proof test coverage (100%) and a very good 90% could mean a whole SIL…

exida explains Blog

Entries tagged with: SIL

- by Dr. William Goble, CFSE

- Thursday, February 09, 2017

- Functional Safety

Getting Good Proof Test Coverage Numbers

- by Loren Stewart, CFSE

- Friday, September 25, 2015

- Functional Safety

How can I improve my SIL?

Click here to read the first entry in this blog series (What is SIL compliance?)

Click here to read the second entry in this blog series (How is SIL Used?)

As we now know, a Safety Integrity Level (SIL) can only be given to a…

- by Loren Stewart, CFSE

- Tuesday, September 22, 2015

- Certification

How is SIL Used?

Click here to read the first entry in this blog series

Once the Safety Integrety Level (SIL) of a product is found, it will be used FOUR ways:

Once the Safety Integrety Level (SIL) of a product is found, it will be used FOUR ways:

- To establish risk reduction requirements

- Probabilistic limits for hardware random failure

- Architectural constraints …

- by Steve Close

- Thursday, October 04, 2012

- Certification

How to Decode an exida IEC 61508 Certificate: Part 2

Now that you know the step-by-step process of product certification, now let’s take a look at the actual information on the certificate.

In the left panel (gray background) you will find an exida certification logo. …

- by Michael Medoff , CFSE, CISA

- Thursday, July 12, 2018

- Industrial Cybersecurity

IEC 62443: Levels, Levels and More Levels

By now we’ve all become familiar with safety integrity levels (SIL), as they have become part of our everyday lives. However, with the recent release of several cybersecurity standards in the IEC 62443 series, things are getting more complicated. This series of standards introduces two more levels…

- by Steve Gandy, CFSP

- Thursday, September 13, 2018

- Functional Safety

Is It Possible to Extend Proof Test Intervals?

I am often asked whether extending proof test intervals will be a problem.

This is a tricky question. The design and engineering SIL calculations for the Safety Instrumented Functions (SIFs) are taking credit for a specific proof test interval with a defined level of coverage, as defined within the…

- by Dr. Eric Scharpf, CFSE

- Monday, April 18, 2011

- Functional Safety

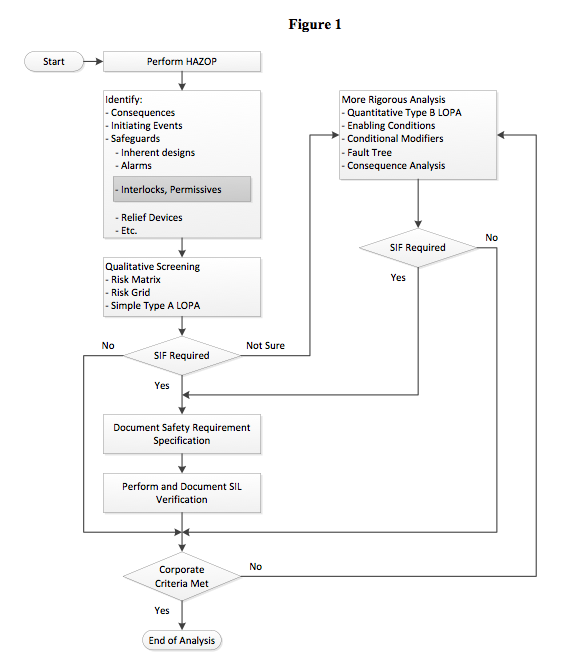

Lifecycle Analysis: It’s Worth the Effort

Performing a risk analysis as part of an IEC61508 / 61511 / ISA 84.01 safety lifecycle process can be quite challenging. How can you be sure you get what you need within budget and how can your team provide the best value for money?…

- by Steve Gandy, CFSP

- Tuesday, October 29, 2013

- Certification

Obtaining My CFSE/CFSP Certification: Why Bother?

It’s an interesting question and one I asked myself. For any engineer and/or professional working in the controls business or process industries where safety-related equipment is required, it is essential (per IEC61511-1 Clause 5.2.2: Organization and Resources) to prove competency to carry out any safety-lifecycle activities. So what does…

- by Hal Thomas, CFSE

- Tuesday, August 30, 2011

- Functional Safety

PHA to LOPA: Part II

In some cases the screening methods will indicate that a SIF is needed. These screening methods can be designed to determine how many orders of magnitude risk reduction is needed, allowing a required SIL to be documented for a particular SIF. The screening…

- by Steve Gandy, CFSP

- Thursday, October 19, 2017

- Functional Safety

Random versus Systematic Faults: What’s the difference?

I saw and responded to a LinkedIn discussion on this very issue, where someone had asked “if I have a misaligned limit switch that fails dangerously, then is it random or systematic? “. This is an intriguing question because many view human error as being systematic and, whereas, this…

- by John Yozallinas, CFSE

- Thursday, February 16, 2017

- Functional Safety

So what does Interference-Free mean? And why do we care?

An Interference-Free component, either as an interface or a defined functional area, is a system component that is neither safety critical (C3) nor safety relevant (C2), but interfaces with such subsystems.

If a component has been shown to be interference free (C1), then it has been demonstrated that no…

- by John Yozallinas, CFSE

- Thursday, April 14, 2011

- Certification

Stepping stones to SIL 3

Imagine. Marketing has just approached the engineering department and says your new safety product must have SIL 3 Capable certification instead of SIL 2 to be successful. You are in the engineering group developing this new product. Now what?

Let’s assume that the “change request” makes…

- by Steve Gandy, CFSP

- Monday, April 28, 2014

- Software

Still Using Excel to do PFD Calculations?

It’s very interesting to me to find that people are still using excel to do PFD calculations. Whereas this is probably okay for simple single element architectures (i.e. single sensor, single logic solver and single final element), it becomes extremely complicated when dealing with redundant architectures. Moreover, for performing…

- by Dr. William Goble, CFSE

- Wednesday, April 19, 2017

- Certification

Tales from the Certification Wars - Proven In Use versus Certification

There have been passionate debates in email and meetings about “Proven In Use” versus IEC 61508 certification. Most debates characterize these evaluation techniques as competing methods. In 2000 when IEC 61511 was being written there were few IEC 61508 certified products on the market. The…

- by Dr. William Goble, CFSE

- Friday, March 04, 2011

- Certification

Tales from the Certification Wars - Who certifies the certification agency?

I have often heard the question “Who says they can issue a certification?” This is often accompanied by “Why can’t I certify my own product?” “Who knows our design better than we do?” Good questions.

The IEC 61508 standard does not require certified products for Functional Safety. …

- by Steve Gandy, CFSP

- Wednesday, February 19, 2014

- Certification

Ten Years Later

It’s hard to believe that the IEC61511 standard has been in existence since 2003, and most companies operating in the process, chemical, and refining industries (or any other hazardous process manufacturer) have adopted its practices. It’s also significant that any plants that were built back then with a…

- by Steve Gandy, CFSP

- Tuesday, August 15, 2023

- Functional Safety

The Importance Of Considering Common Cause with Redundant Systems

Common Cause is one of those variables that is not always considered important when it comes to SIL compliance. And yet, for redundant systems, it can have a significant impact on the PFDavg and Risk Reduction achieved (in Low Demand mode) or PFH (in high or continuous mode). Most of the…

- by Iwan van Beurden, CFSE

- Tuesday, June 14, 2016

- Software

The Meaning of Tool Integration

What does tool integration mean? One can argue it is the ability for different tools to talk to each other and exchange data. Though this may be true from a typical software tool integration, a common definition of integrate, i.e. to bring together or incorporate (parts) into a whole…

- by Dr. William Goble, CFSE

- Tuesday, June 07, 2011

- Certification

The Weakest Link

One of the objectives of new performance based standards like IEC 61508 is to allow performance metrics (like PFDavg for low demand systems) to identify the weak links in any proposed design. Obviously, it is not necessary to put effort into design and spend money on areas…

- by Dr. William Goble, CFSE

- Thursday, October 13, 2011

- Functional Safety

Two Billion Hours

When I studied Reliability Engineering in graduate school, I was taught that failure rate data came from field failure studies. I assumed that operating companies always kept accurate records when a piece of equipment failed. I also assumed that someone would investigate the failures and assign a root cause.…